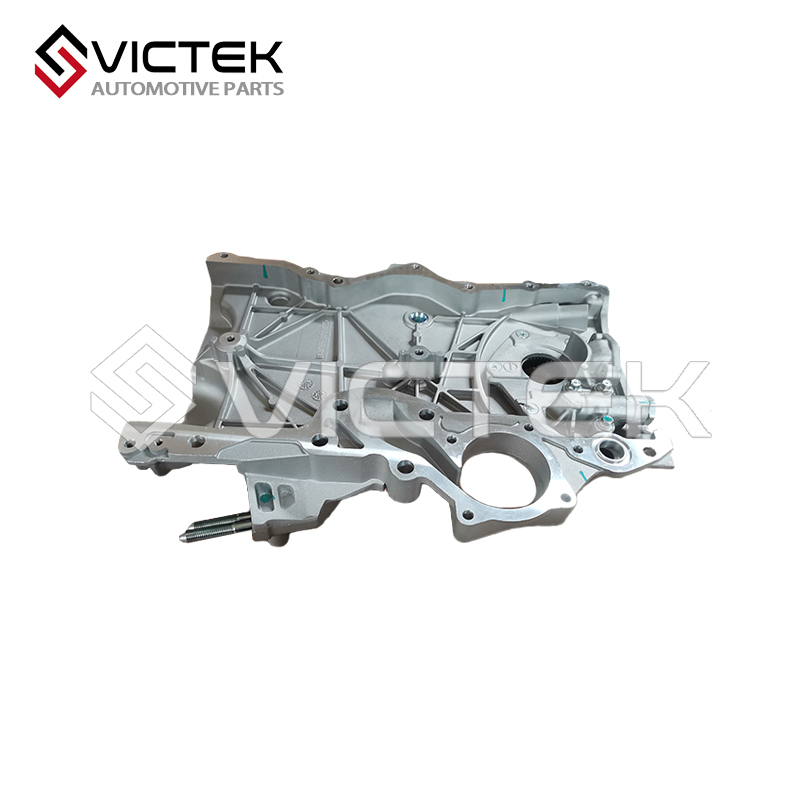

Z300-1060A080-A01

Oil supply: Sucks oil from the pan through the inlet screen and pushes it through the engine’s oil passages—coating every moving part with a thin, protective oil film to reduce friction.

Pressure regulation: The built-in pressure relief valve releases excess oil back to the pan if pressure gets too high (prevents damage to oil lines, gaskets, or engine parts) and ensures pressure doesn’t drop too low (avoids oil starvation).

Debris filtration: The inlet screen traps dirt, metal shavings, or sludge from the oil—stops contaminants from reaching sensitive components (like piston rings or camshafts) and causing scratches or clogs.

Fits These: All Zotye Z300 variants (matches the engine’s oil flow requirements, mounting points, and pressure specs—confirm via VIN).

Won’t Fit These:

Other Zotye models: Like Z500, T600, or SR7—different engine designs, oil pump sizes, or drive systems (pump won’t work or leaks).

Non-Zotye vehicles: Even if the shape looks similar, their engine block specs and oil pressure needs don’t match (causes oil starvation or pressure damage).

Zotye Z300 with modified engines: Aftermarket engine upgrades (like bored cylinders) change oil flow needs—original pump can’t keep up (leads to overheating).

Prep: Drain the Z300’s engine oil and remove the oil pan (to access the pump). Disconnect the pump’s drive connection from the crankshaft (may need to remove timing components like the chain or belt).

Remove old pump: Unbolt the old pump from the engine block—check the mounting surface for damage (repair if needed). Clean the oil pan and inlet screen to remove debris.

Install new pump: Apply a thin layer of oil-resistant gasket sealant to the pump’s mounting surface (prevents leaks). Bolt Z300-1060A080-A01 to the engine block (tighten to Zotye’s exact torque specs—over-tightening cracks the block). Reconnect the crankshaft drive and replace the oil pan.

Test: Refill the engine with Zotye-recommended oil. Start the engine and use a pressure gauge to verify oil pressure (should be 20–60 psi). Check for leaks around the pump and oil pan.

Change oil regularly: Follow Zotye’s schedule (usually every 5,000–7,500 km)—old, dirty oil clogs the inlet screen and wears the pump’s gears.

Check oil pressure monthly: If the Z300’s oil pressure light comes on (or gauge reads low/high), stop driving immediately—have the pump inspected (low pressure = starvation; high = valve failure).

Inspect inlet screen during oil changes: Clean or replace the screen if it’s clogged with debris (ensures steady oil flow to the pump).

Avoid low oil levels: Never run the Z300 with oil below the “min” mark—starves the pump of oil (causes gears to grind and fail).

Fits: All Zotye Z300 variants (matches engine oil flow needs, mounting points, and pressure specs; confirm via VIN).

Won’t Fit: Other Zotye models (e.g., Z500, T600, SR7) with different engine/drive systems, non-Zotye vehicles (mismatched block specs/pressure needs), or Z300 with modified engines (aftermarket upgrades alter oil flow requirements).

Oil supply: Delivers oil through engine passages, coating moving parts with a protective film to reduce friction.

Pressure regulation: Relief valve releases excess oil (prevents line/gasket damage) and maintains stable pressure (avoids oil starvation).

Debris filtration: Inlet screen traps dirt/metal shavings, protecting sensitive components from scratches/clogs.

Requires certified technicians (2–3 hours): Involves draining oil, removing the oil pan/timing components, cleaning the mounting surface, applying gasket sealant, bolting the pump to torque specs, reconnecting the crankshaft drive, and refilling oil.

Post-install test: Verify oil pressure (20–60 psi) with a gauge and check for leaks around the pump/oil pan.

Regular oil changes: Follow Zotye’s 5,000–7,500 km schedule to prevent screen clogging and gear wear.

Monthly pressure checks: Stop driving if the oil pressure light/gauge shows (low = starvation; high = valve failure) and inspect the pump.

Screen inspection: Clean or replace the inlet screen during oil changes to ensure steady oil flow.

Avoid low oil levels: Prevent pump gear grinding by keeping oil above the “min” mark.

=

Contact us