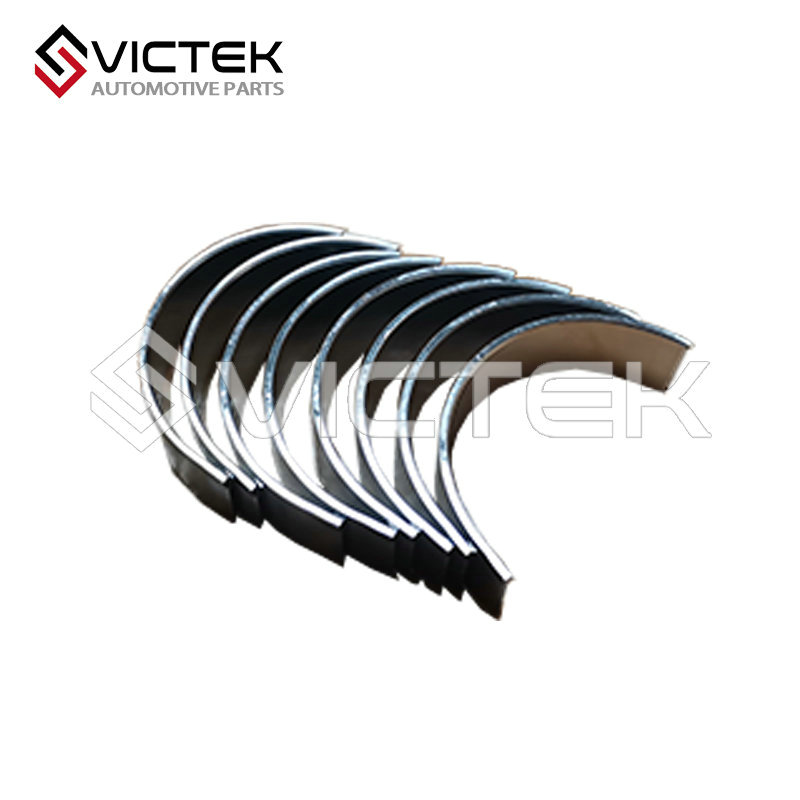

Let’s get straight to it—this isn’t just a “small bearing” in your Haima S7’s engine. It’s the

wear-resistant load-bearing core between the crankshaft and connecting rod: a precision-engineered thin-walled bearing, typically made of high-tin aluminum alloy or copper-lead alloy with a wear-resistant coating. Mounted between the connecting rod big end and the crankshaft journal, it acts as a critical buffer and force-transmitting component. Think of it as the “engine’s friction reducer and power transmitter”—it minimizes friction between the rotating crankshaft and the reciprocating connecting rod, transfers the

piston’s explosive force to the crankshaft, and absorbs vibration during engine operation. Without it, the crankshaft and connecting rod would wear out instantly, leading to severe engine damage or even seizure.

This connecting rod bearing set (484Q-11-225-T~227) is exclusively tailored for Haima S7 with 484Q series engines—always confirm your vehicle’s VIN and engine model to ensure a perfect match! It’s calibrated to the S7’s engine specs: its inner diameter and thickness match the crankshaft journal size (ensuring proper oil clearance), its material strength syncs with the engine’s maximum torque (resisting impact loads), and its dimensions align with the connecting rod big end (secure fit). Opt for generic bearings? You’ll face issues: improper clearance (oil leakage or insufficient lubrication), weak material (rapid wear), or mismatched size (engine knocking).

As a vital component of the engine’s crank-connecting rod mechanism, it undertakes three key roles for your Haima S7:

Minimize friction and wear: Its smooth, wear-resistant surface and precise oil clearance (usually 0.02–0.05mm) allow a thin oil film to form between the bearing and crankshaft journal. This separates the two metal parts, reducing friction and preventing direct contact wear.

Transmit explosive power: It bears the enormous pressure generated by the piston’s combustion (up to tens of thousands of Newtons) and transfers this force to the crankshaft, converting the piston’s linear motion into the crankshaft’s rotational motion—powering the vehicle forward.

Absorb vibration and buffer impact: The soft metal material and flexible structure absorb the vibration and impact caused by the engine’s high-speed operation. This stabilizes the crank-connecting rod mechanism and reduces noise.

![484Q-11-225-T~227 484Q-11-225-T~227]()

This 484Q-11-225-T~227 connecting rod bearing set only works for Haima S7 equipped with 484Q series engines—wrong fit = catastrophic engine damage:

Replacing connecting rod bearings involves precise clearance measurement and engine disassembly—DIY is impossible and risky:

Engine prep: Techs disassemble the engine (remove cylinder head, oil pan, connecting rods), then clean the crankshaft journals and connecting rod big ends thoroughly.

Bearing selection: They check the crankshaft journal wear and select the correct bearing size (the “T~227” suffix indicates different thicknesses for wear compensation).

Install new bearings: They fit the upper and lower bearing shells into the connecting rod big end (aligning the locating bosses), then bolt the connecting rod cap to Haima’s exact torque specs (even torque to avoid bearing deformation).

Clearance measurement: Critical step—techs use a feeler gauge or plastic gauge to check the oil clearance. Improper clearance (too tight/loose) leads to bearing seizure or oil leakage.

Reassembly & test: They reassemble the engine, refill with specified oil, and start the engine for idle run-in (monitors for abnormal noise). A road test confirms smooth operation.

Use Haima-specified engine oil: Always use oil that meets the 484Q engine’s viscosity and quality standards. Low-quality oil breaks down easily, losing lubrication ability.

Change oil and filter regularly: Replace engine oil and filter per the S7’s maintenance schedule (usually every 5,000–7,500km). Contaminated oil contains metal particles that scratch the bearing surface.

Avoid cold starts and overloads: Let the engine warm up before driving (builds oil pressure). Avoid long-term high-speed driving or heavy loads—reduces bearing stress.

Monitor engine abnormal noise: If a rhythmic “knocking” sound comes from the engine (especially at idle), stop driving immediately. This indicates bearing wear or clearance issues—delays cause crankshaft damage.

![484Q-11-225-T~227 484Q-11-225-T~227]()

This is an exclusive bearing set for Haima S7 with 484Q series engines (confirm VIN for fitment). Made of high-tin aluminum/copper-lead alloy with wear-resistant coating, it’s mounted between the connecting rod big end and crankshaft journal.

Its core functions: Form an oil film to reduce friction/wear between crankshaft and connecting rod, transfer piston combustion power to crankshaft (driving the vehicle), and buffer engine vibration/impact.

It only fits Haima S7 484Q variants, incompatible with other Haima models (e.g., S5, M6) or non-Haima vehicles. Installation requires certified techs to measure oil clearance and torque bolts properly. Maintain by using specified oil, regular oil changes, and checking for abnormal engine knocking. Original parts are a must—aftermarket ones risk rapid wear or improper clearance, causing severe engine damage.

Contact us

![484Q-11-225-T~227 484Q-11-225-T~227]()